- Home

- >

- Products

- >

- Suspension Insulator

- >

Suspension Insulator

- Information

- Product Description

Suspension Insulator Introduction

Insulators are essential to the safe and stable distribution of electricity generated by power plants. Suspension insulators support transmission lines on steel towers, isolating the lines from the towers. Disc insulators play a key role in safely supplying electricity. Suspension insulators come in two or more configurations depending on the transmission voltage and usage environment.

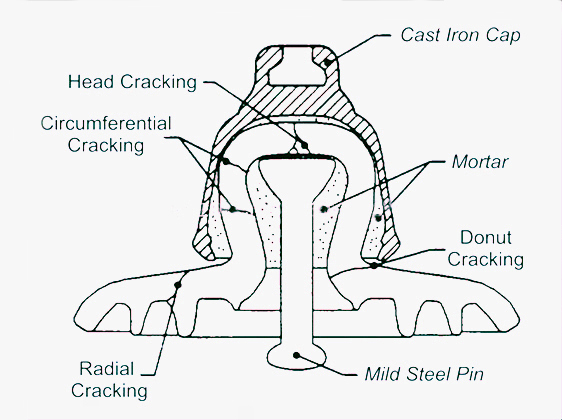

1. Porcelain disc insulator structure

1) End fittings: Ball & Socket (Cap & Pin), Tongue & Clevis. The ball pin can be equipped with zinc sleeve to prevent pin corrosion.

2) The porcelain is a uniform brown or gray color, non-porous having high dielectric mechanical and thermal strength, and free from internal stresses, blisters, laminations, or other defects, which might in any way render it unsuitable as insulator shells. The porcelain is smoothly glazed to remain unaffected by climatic conditions, Ozone, acids, zinc, or dust. The glaze has a bright luster, smooth surface, good performance under extreme weather conditions of tropical climates, and is dust resistant.

3) The cap and pin of the suspension-type insulator are hot dip galvanized in accordance with ISO 1461 or BS 729. The pin should move freely in the cap socket but not disengage while in service. The cap is made of heat-treated cast iron, free from cracks, shrinks, air holes, and rough edges. The pin is made of forged steel. The locking device is made of stainless steel, with an "R" clip or a "W" clip.

4) The electrical and mechanical characteristics of disc insulators conform to the technical parameters of the tender specifications and relevant standards.

5) Internal structure of a porcelain disc insulator is a conical head or straight head. The entire surface of the porcelain insulator that exposes after assembly is a smooth uniform glazed surface without any form of defects.

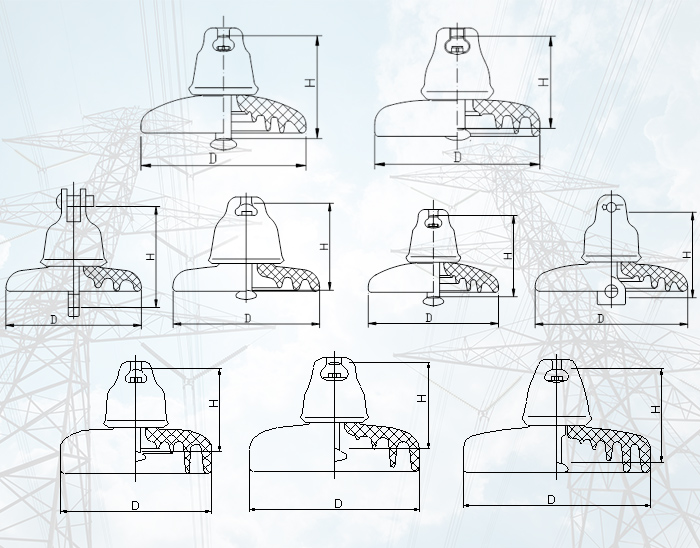

2. Technical Specifications

Type | U70BL | U100BL | U120B | U160BL | ||

Unit Spacing (H) - mm | 146 | 146 | 146 | 170 | ||

Nominal Diameter (D) -mm | 255 | 255 | 255 | 280 | ||

Coupling size | 16A/16B | 16A/B | 16A/B | 20 | ||

Nominal Creepage Distance-mm | 320 | 295 | 320 | 305 | ||

Rated E & M Failing Load-kN | 70 | 100 | 120 | 160 | ||

Routine Tensile Load-kN | 35 | 50 | 60 | 80 | ||

Impact Strength-N.m | 6 | 7 | 7 | 10 | ||

Power Frequency Withstand | Wet-kV | 40 | 40 | 40 | 40 | |

Dry-kV | 70 | 70 | 70 | 70 | ||

Dry Lighting Impulse Withstand Voltage-kV | 110 | 110 | 110 | 110 | ||

Power Frequency Puncture Voltage-kV | 110 | 110 | 110 | 110 | ||

Radio Interference Voltage | Test Voltage to Ground-kV | 10 | 10 | 10 | 10 | |

Max. RIV at 1MHz-uV | 50 | 50 | 50 | 50 | ||

Weight-kg | 5.0 | 5.7 | 5.8 | 7.0 | ||

3. Manufacturing Process

The design of porcelain insulators shall minimize the effect of local corona formation and discharge likely to cause radio interference and shall facilitate inspection, cleaning, repair, and hotline maintenance. All corresponding parts are to be made to gauge the interchangeability.

4. Advantages

High reliability is achieved through long-term experience and technology accumulation.

Selected high-quality raw materials

High-strength porcelain insulators with a higher amount of alumina, Adequate Materials Analysis Techniques, Strict incoming inspection, Selected high-quality raw materials, Optimal Design Engineering, Straight head design, less stress concentration, Lightweight and compact design, Advanced Manufacturing Technology, Uniform quality through continuous firing and production control, Control of Thermal Expansion of Porcelain, Molding without material damage, Precise assembly without stress concentrations, Long-term performance evaluation

5. Standard

IEC 60383, IEC 60120 & ANSI C29.2

6. Packing

The porcela disc insulators are packed with wooden crate on pallet.

7. Application

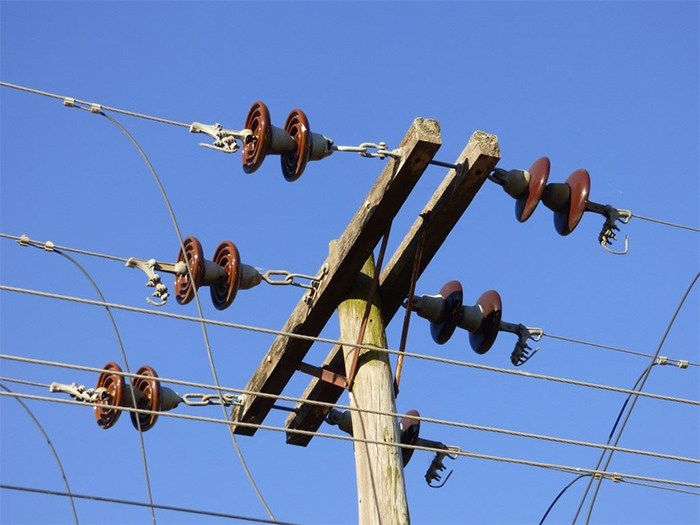

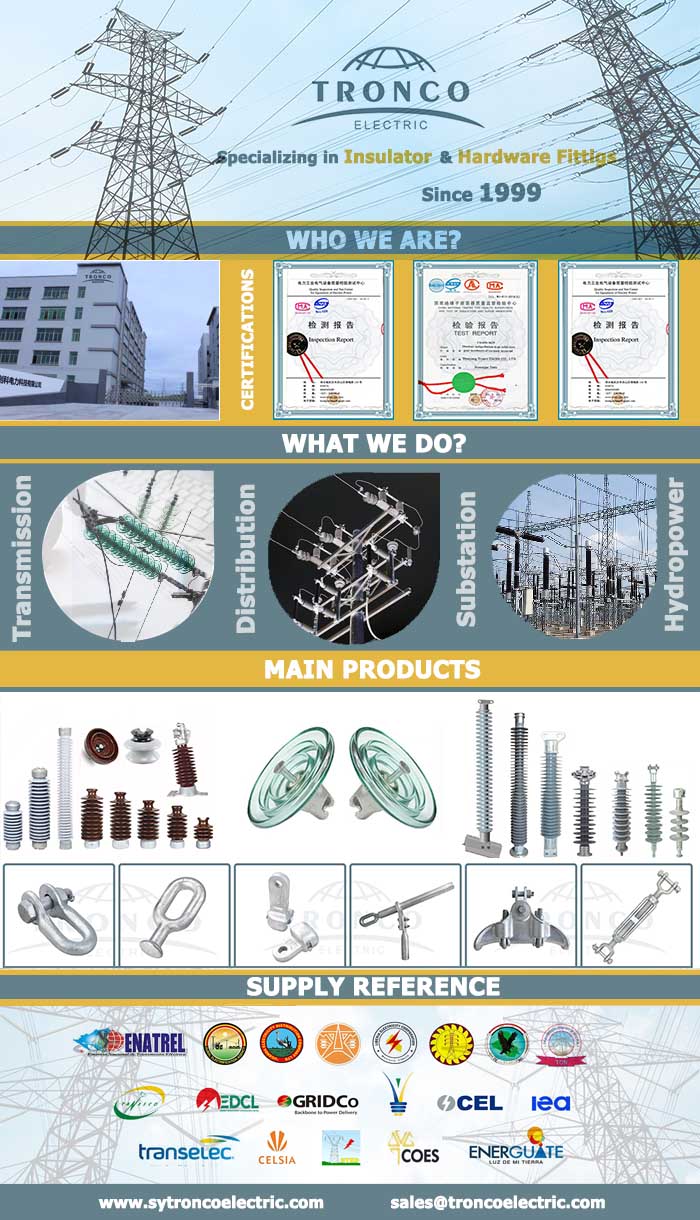

Porcelain suspension insulator is widely used for power transmission, distribution, and substation systems with disc insulators' best electrical and mechanical performance.

Porcelain disc insulators are the most widely used in strings, Suspension type insulators can be used for any voltage depending on the number of units mounted in series for transmission and distribution lines.

Voltage & Mechanical Range: 10kV-500kV 40kN-530kN.