- Home

- >

- Products

- >

- Post Insulator

- >

Post Insulator

- Information

- Product Description

- Video

Station Post Insulator Description

Materials: The porcelain post insulators body is made from high quality aluminium oxide porcelain, C120 or C130, which conforms to IEC 60672. Glazing is brown, or gray in color. End fittings are made in hot dip galvanized malleable cast iron, or spheroidal graphite cast iron. The galvanizing coating thickness is according to standard ISO 1461 or BS 729. All iron and steel parts are galvanized after sawing, shearing, drilling, punching, filling, bending and machining, etc.

Standard dimensions for fittings are according to IEC 60273.

Pitch circle diameter P.C.D. (mm) | Depth of tapped blind holes (mm) | Number of holes | Bolt holes tapped | Bolt holes plain (mm) | Nominal maximum diameter of mounting face (mm) |

| 76 | 12 | 4 | M12 | 115 | |

| 127 | 18(22) | 4 | M16 | 165 | |

| 178 | 4 | 18 | 225 | ||

| 200 | 4 | 18 | 245 | ||

| 225 | 4 | 18 | 270 | ||

| 254 | 8 | 18 | 300 | ||

| 275 | 8 | 18 | 320 | ||

| 300 | 8 | 18 | 345 | ||

| 325 | 8 | 18 | 370 | ||

| 356 | 8 | 18 | 400 | ||

| 375 | 8 | 18 | 420 |

The porcelain insulators post type is sound, free from defects, and thoroughly vitrified and glazed in accordance with IEC 60168, IEC 60372, or ANSI C29.9. Glazing is smooth, hard, of a uniform shade of brown or gray, and completely covers all exposed parts of the insulators and follows the relevant standards.

All insulators supplied by Tronco Electric satisfactorily withstand the specified climatic and service conditions, and the strengths of insulators are designed according to the client's specifications.

1. Technical datasheet ANSI insulators

ANSI Class | 202 | 205 | 208 | 210 | 214 | |

Basic Impulse Insulation Level (kV) | 95 | 110 | 150 | 200 | 250 | |

Usual Line Voltage (kV) | 7.5 | 15 | 23 | 34.5 | 46 | |

Leakage distance/in (mm) | 10-1/2(267) | 15-1/2(394) | 24(610) | 37(940) | 43(1092) | |

Cantilever Strength/Ib (kN) | 2000(8.9) | 2000(8.9) | 2000(8.9) | 2000(8.9) | 2000(8.9) | |

Tensile Strength/Ib (kN) | 7000(31.1) | 8500(37.8) | 10000(44.5) | 12000(53.4) | 14000(62.3) | |

Torsional Strength/in-Ib (N.m) | 6000 (678) | 7000 (791) | 8000 (35.6) | 10000 (44.5) | 12000 (53.4) | |

Compression Strength /Ib (kN) | 10000(44.5) | 10000(44.5) | 10000(44.5) | 15000(66.7) | 15000(66.7) | |

Critical Impulse Flashover Voltage, Positive (kV) | 105 | 125 | 170 | 225 | 280 | |

Withstand Voltage | Low Frequency, Wet/kV | 30 | 45 | 60 | 80 | 100 |

Impulse/kV | 95 | 110 | 150 | 200 | 250 | |

Radio-Influence Voltage Data | Test Voltage to Ground/kV | 5 | 10 | 15 | 22 | 30 |

Maximum RIV at 1000 kHZ/µV | 50 | 50 | 100 | 100 | 200 | |

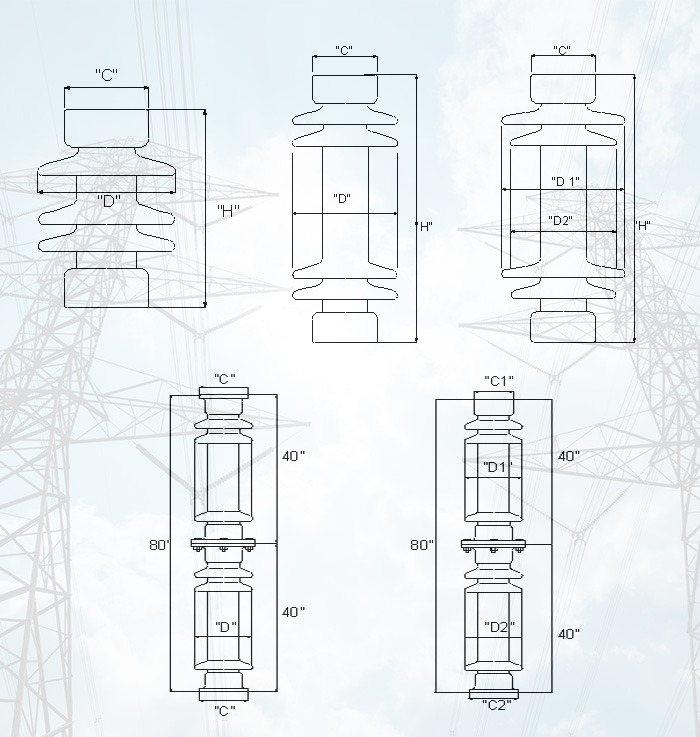

Height-“H”/in(mm) | 7-1/2(190) | 10(254) | 14(356) | 18(457) | 22(559) | |

Shed diameter/in(mm) | 6-1/2(165) | 6-1/2(165) | 6-1/2(165) | 6-7/16(164) | 7-1/4(184) | |

Bolt circle diameter/in(mm) | 3 | 3(76) | 3(76) | 3(76) | 3(76) | |

(4)Tapped holes, size/in | 1/2-13 | 1/2-13 | 1/2-13 | 1/2-13 | 1/2-13 | |

Cap diameter-“C”/in (mm) | 4-1/4(108) | 4-1/4(108) | 4-1/4(108) | 4-1/4(108) | 4-1/4(108) | |

Net Weight/Ib (kg) | 15(6.7) | 21(9.3) | 26(11.6) | 32(14.2) | 41(18.2) | |

IEC post insulators

Rated voltage (kV) | Nominal voltage (kV) | Power frequency withstand voltage ≥ | Lightning impulse withstands voltage | Wet switching impulse withstand voltage ≥ | |

| Dry | Wet | ||||

| 126 | 110 | 265 | 230 | 550 | - |

| 145 | 132 | 375 | 275 | 650 | - |

| 252 | 220 | 495 | 460 | 1050 | - |

| 363 | 330 | - | 680 | 1550 | 1050 |

| 550 | 500 | - | 790 | 1950 | 1240 |

| 800 | 750 | - | 950 | 2350 | 1675 |

| 1100 | 1000 | - | 1300 | 2680 | 1860 |

Aluminous or Portland cement are used as the bonding agent between the porcelain and the metal parts. The porcelain is manufactured by the wet process of the homogeneous structure free from laminations, cavities, or other flaws affecting its mechanical or dielectric strength. The post-type insulator is well-vitrified and nonporous and has a brown-colored glaze. The porcelain of each insulator unit is reasonably free from warp and impervious to moisture and has a uniform, smooth, hard glaze which is free from imperfections such as spots, blisters, and burrs that would in any way impair the unit for the service for which it is to be used.

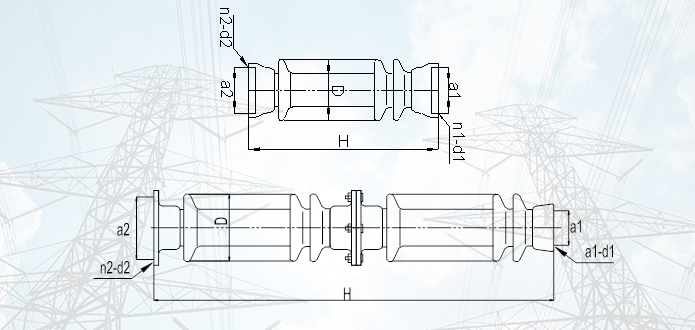

Each end cap is high-grade malleable iron and machine-faced. Galvanized steel bolts or cap screws are furnished for the assembly of all stacking units.

Porcelain post insulators are mechanically dimensioned for stresses arising from wind load, tensile forces, and movement in connections as well as for short circuit and earthquake forces as specified. Post-type insulators are electrically strong enough to withstand lightning impulse and switching impulse/or power frequency voltage specified. And ceramic post insulators can be used either upright or inverted.

Post insulators comprise fully interchangeable units of either the pedestal or solid core cylindrical type. The completed units are uniform in height and bolt locations so that they are interchangeable.

The use of post insulators comprising units graded according to mechanical strength is not precluded, provided corresponding units are fully inter-changeable and clearly identified according to their mechanical characteristics. The metal fittings of post insulators are out-flange type and require no cement inside porcelain. The end support of insulators accepts the torsion loading specified. The torsion imposed on the insulator is the bending moment on the end of the bus, due to the wind load and the short circuit current electromagnetic force on the bus.

Cantilever loading on an insulator subject to simultaneous wind and short load must not exceed 75% of the rated cantilever strength. Bolting surfaces are parallel, and the galvanizing on the faces is uniform and smooth, to ensure proper seating of surfaces when they are bolted together.

2. Porcelain post insulators manufacture process

3. Application

Post type insulators are widely used in electrical power systems for various applications due to their excellent electrical insulation properties, mechanical strength, and resistance to environmental factors. Key applications:

Transmission & distribution lines.

Substations

Switchgear & disconnector

Railway electrification

Renewable energy

Overall, porcelain post insulators play a critical role in the operation of electricalpoer systems by providing insulation and mechnical support in a wide range of applications.

Free of internal stresses, minimum porosity

No measurable aging

High performance consistency

Puncture proof