Polymer Post Insulator

- Information

- Product Description

- Video

Polymer Post Insulator

Composite post insulator consists of a fiberglass core, top and bottom flanges, and HTV silicone rubber housing. Line post insulators are used for horizontal and vertical assembly in high-voltage and medium-voltage power lines.

1. Polymer insulators characters:

Shed connected with the core by integral forming

Metal end fittings, core, and sheds connected by new crimping process

The thickness of housing > 3mm, uniform thickness, confirm to IEC Standard

Acid-resistant, high-temperature-resistant an epoxy fiberglass core

The material of metal end fittings is used with hot galvanization and technology of rare earth aluminum coating to avoid coating shedding when crimping, prolonging the service life of the product.

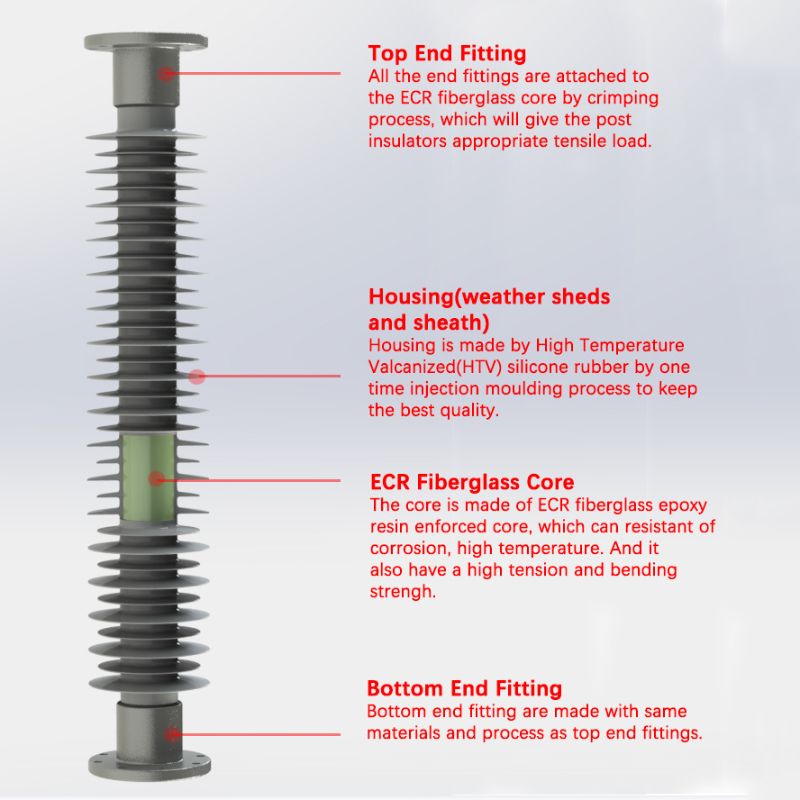

2. Post insulators structure

Core rod

The core rod of the insulator is made of a high-quality, epoxy resin, Fiberglass rod that has been specially formulated for electrical and mechanical applications.

Housing

The housing (includes sheath and sheds)of the insulator is one-piece, high-temperature vulcanized, injection molded silicone rubber that is chemically bonded to the core rod. This ensures that the interface between the rubber and rod is impenetrable against moisture ingress. Tronco uses its own proprietary silicone rubber formula in the manufacture of its insulators. the formulations have silicone rubber as the base polymer material with additives to enhance its performance in wet contaminated environments.

End Fitting

Station post insulator, both of the end fittings are flanges.

3. Technical data sheet:

Type Model | Specified cantilever load (kN) | Rated voltage (kV) | Section height (mm) | Creepage distance (mm) | Min. wet power frequency withstand voltage (kV) | Min. Lightning impulse withstand voltage (kV) |

FZSW-24/10 | 10 | 24 | 311 | 800 | 50 | 125 |

FZSW-35/8 | 8 | 35 | 445 | 1054 | 150 | 210 |

FZSW-66/12 | 12 | 66 | 770 | 1930 | 175 | 325 |

FZSW-110/10 | 10 | 110 | 1500 | 4280 | 230 | 550 |

FZSW-145/6 | 6 | 145 | 1500 | 4010 | 405 | 725 |

FZSW-220/12 | 12 | 220 | 2300 | 6260 | 395 | 1000 |

FZSW-330/12 | 12 | 330 | 3350 | 9400 | 800 | 1500 |

4. Manufacture process

1) Preparation process

2) Raw material mixing process

3) Core rod and metal fitting assembly process

4) Injection molding process

5) Flash-removing process

6) Metal fitting crimping process

7) Routine test & Sample test

8) Packing and delivery

5. Fabrication and testing equipment

Injection machine

Crimping machine

HV electrical test facility

Bending and torsional tester

Zinc coating device

6. Product Features

Durable Construction: The composite post insulator is crafted with utmost precision using premium-grade materials. This ensures its longevity and resistance to various environmental conditions, including moisture, UV rays, and chemical substances.

Superior Insulation: With excellent electrical properties, this insulator effectively isolates conductive components, preventing leakage currents and enhancing the overall performance of the electrical system.

Lightweight Design: The use of advanced composite materials makes this post insulator considerably lighter compared to traditional porcelain insulators. Its lightweight construction allows for easy handling, installation, and maintenance.

Corrosion Resistance: The insulator's composite construction protects it against corrosion, enabling it to withstand harsh environments and ensuring a longer service life.

High Mechanical Strength: This post insulator possesses excellent mechanical strength, allowing it to withstand heavy loads, vibrations, and extreme temperatures without compromising its integrity.

Versatile Application: Suitable for various substation applications, this composite post insulator is compatible with a wide range of electrical equipment, including circuit breakers, transformers, and disconnect switches.

7. Applications

As an insulating barrier between conductive components in substations, it prevents the flow of electricity through the structure, ensuring reliable and safe operation of the electrical system. Its composite construction offers superior strength and insulation properties, complemented by its lightweight design for easy handling and installation.

FAQ (Frequently Asked Questions)

Q: What are the advantages of using a composite post insulator?

A: Composite post insulators offer several advantages including exceptional durability, superior insulation properties, lightweight design, corrosion resistance, and high mechanical strength. These features enhance the performance and reliability of electrical systems.

Q: Can the composite post insulator be used in outdoor applications?

A: Yes, the composite post insulator is specifically designed to withstand various outdoor conditions. Its corrosion-resistant properties and UV resistance make it suitable for use in harsh environments.

Q: Are these post insulators suitable for high voltage applications?

A: Absolutely! The composite post insulators are engineered to cater to medium to high voltage applications. They are manufactured in compliance with industry standards, ensuring safe and efficient operation.

Q: How often should the composite post insulators be inspected or maintained?

A: Regular inspections should be conducted as per industry guidelines to ensure the integrity and reliability of the composite post insulators. However, the maintenance frequency may vary depending on the specific operating conditions and environmental factors

Lightweight

Good anti-pollution

High antifouling property

Strong shock resistance

Stable performance