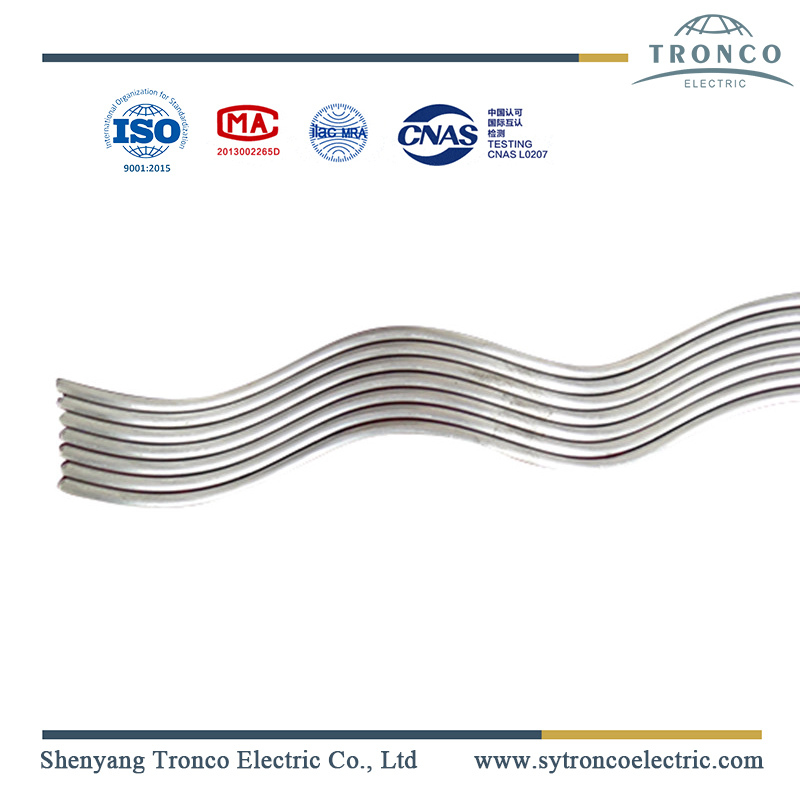

Armor Rod

- Information

- Product Description

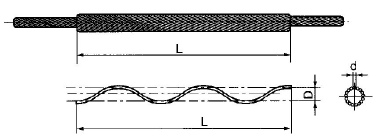

Armor Rods Description

Armor rods are installed on the conductor at the point of suspension to protect the conductor against bending, compression, abrasion, and arc-over. Armor rods are made of aluminum alloy metal, performed type and size recommended by Tronco Electric to fit the specified conductor.

Armor rods are suitable for maintenance using hot line tools and are fitted at suspension points of line conductors except for jumper suspension points.

1. Technical specifications

Install performed armor rods in accordance with approved recommendations by Tronco Electric. Centre rods in each suspension clamp so that the variation from the center line of the clamp and the mid-point of the rod is not more than 50 mm. Exercise proper caution in seating the last few rods of the set so that the conductor surface is not damaged.

Type | Conductor Dia. | Dimensions (mm) | A Group | Weight (Kg/group) | |||

Min(mm) | Max(mm) | d | L | No.of strands | Code | ||

FYH-099105 | 9.90 | 10.50 | 4.24 | 1320 | 9 | Red | 0.490 |

FYH-105111 | 10.51 | 11.10 | 3.17 | 1320 | 10 | Blue | 0.420 |

FYH-111124 | 11.11 | 12.45 | 4.24 | 1370 | 10 | Green | 0.565 |

FYH-124132 | 12.40 | 13.25 | 4.24 | 1420 | 11 | Blade | 0.545 |

FYH-132140 | 13.20 | 14.00 | 4.24 | 1470 | 11 | Yellow | 0.670 |

FYH-140148 | 14.01 | 14.05 | 4.62 | 1520 | 11 | Brown | 0.820 |

FYH-148154 | 14.06 | 15.41 | 4.62 | 1570 | 12 | White | 0.925 |

FYH-154166 | 15.42 | 16.65 | 4.62 | 1630 | 12 | Orange | 0.960 |

FYH-172178 | 16.66 | 17.25 | 4.62 | 1600 | 13 | Purple | 1.075 |

FYH-178188 | 17.20 | 17.05 | 5.10 | 1730 | 12 | Red | 1.205 |

FYH-188199 | 17.00 | 18.80 | 5.10 | 1830 | 12 | Blue | 1.306 |

FYH-199215 | 10.01 | 19.90 | 5.10 | 1830 | 13 | Green | 1.470 |

FYH-215230 | 10.01 | 21.50 | 6.35 | 1930 | 11 | Brown | 1.975 |

FYH-230236 | 21.51 | 23.60 | 6.35 | 2000 | 12 | White | 2.210 |

FYH-236248 | 23.01 | 24.00 | 6.35 | 2030 | 13 | Orange | 2.450 |

FYH-248258 | 23.01 | 25.80 | 6.35 | 2240 | 13 | Purple | 2.700 |

FYH-258263 | 24.01 | 26.30 | 7.87 | 2340 | 11 | Red | 3.675 |

FYH-263279 | 25.01 | 27.00 | 7.87 | 2390 | 12 | Blue | 4.010 |

FYH-279289 | 26.01 | 20.95 | 7.87 | 2440 | 12 | Green | 4.100 |

FYH-289307 | 27.01 | 30.70 | 7.87 | 2540 | 12 | Brown | 4.350 |

FYH-307337 | 20.0 | 33.70 | 7.87 | 2540 | 13 | White | 4.715 |

FYH-337353 | 30.01 | 35.30 | 9.27 | 2540 | 12 | Orange | 6.040 |

FYH-353353 | 30.01 | 36.60 | 9.27 | 2540 | 13 | Purple | 6.540 |

2. Applications and Functions of Preformed Armor Rods

Preformed armor rods play a crucial role in protecting and preserving the integrity of conductors and strands in transmission lines and cables. These versatile tools shield cables from a range of potential damages, including wear and tear, bending, shaking, compression, abrasion, and other forms of physical harm. Additionally, they offer valuable restorative repair capabilities, making them a wise investment for any industry that relies on conductor cables.

The Importance of Preformed Armor Rods in Transmission Lines

Through their unique design and composition, preformed armor rods provide essential protection for transmission lines and cables. One of their primary functions is preventing physical damage to the cable itself. Beyond that, they also serve a vital role in repairing aluminum-based conductors, helping to restore their mechanical strength and conductivity - two critical factors for any conductor cable.

Industries and Sectors Where Preformed Armor Rods are Utilized

Preformed armor rods find applications in a wide range of industries, including power electrical industries, the telecommunications sector, and various areas of architecture and construction. These rods are specifically designed to protect conductors from multiple wear-down factors, such as compression and bending, by refacing the ends through abrasion. Moreover, their main application lies in safeguarding transmission lines and cables against the damaging effects of natural elements and deterioration.

Compatibility with Different Conductors

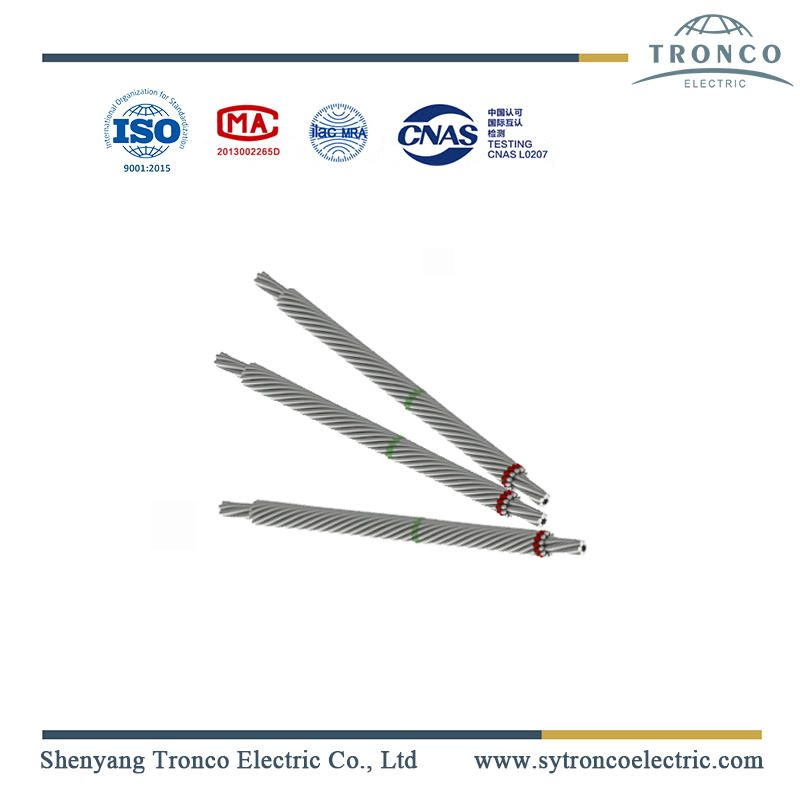

Preformed armor rods are constructed using materials like aluminum alloy or copper-clad steel. This construction allows them to be used with various types of conductors, including ACSR, AAC, AAAC, ACSS, SSAC, TW, ACAR, and other similar conductors. Their versatility and compatibility make preformed armor rods suitable for a range of applications involving different conductor types.

Additional Benefits of Preformed Armor Rods

In addition to protecting and repairing conductors, preformed armor rods offer several other advantages. When used for spans greater than 300 feet (91 meters), these rods become an essential component for ensuring the safety and durability of transmission lines and cables. By mitigating potential damages and maintaining the mechanical integrity of conductors, preformed armor rods contribute to long-term cost savings and overall operational efficiency.

Whether in power electrical industries, telecommunications, or construction, the use of preformed armor rods is essential for safeguarding the performance and longevity of transmission lines and cables. These versatile tools provide unparalleled protection and restorative capabilities, making them a valuable asset for any industry that relies on conductors.

3. Packing and storage

The preformed armor rods are packed in the plywood case, and stored in the warehouse.

4. The Advantages of Preformed Armor Rods

Preformed armor rods offer a range of key features that make them highly advantageous in various applications. Here are some of the notable benefits:

Color Coding for Easy Installation. Each preformed armor rod is available in different colors, such as yellow, green, or black. This color coding system allows for easier installation, as it helps with the alignment of the rods. By quickly identifying the color-coded armor rod, installers can streamline the installation process.

Damage Repair and Restoration. Preformed armor rods can be incredibly useful in situations where aluminum conductors or ACSR have sustained less than 50% damage on their outer strands. These rods can assist in restoring the rated conductance and strength of the conductor back to 100%, improving overall performance and reliability.

Protection Against Vibration. In addition to safeguarding against natural elements and deterioration, preformed armor rods also offer protection from the effects of vibration. They aid in helping the conductor cable withstand fatigue forces caused by Aeolian-type vibration, ensuring long-lasting durability in demanding environments.

Compatibility with Tapped Conductors. Certain aluminum conductors, like ACSR, can be tapped with preformed armor rods. However, it is essential to thoroughly brush the conductor and apply an oxide inhibitor before tapping. This ensures optimal conductivity and a secure connection.

Straightforward Installation. Installing preformed armor rods on a transmission line is a simple process that does not require any technical skills or expertise. A single individual can easily install these rods using a standard toolset. Therefore, there is no need for specialized tools or extensive training.

5. How to Install Preformed Armor Rods

The installation of preformed armor rods is straightforward and can be done following these steps:

Mark the Conductor. Start by indicating a small identification mark on the conductor, marking the spot where the installation of the armor rod will begin. This mark will be helpful during the installation process.

Check the Color Code. Inspect the armor rod for its color-coded mark, ensuring it aligns with the external layer of the conductor. This will ensure proper fitting and alignment during installation.

Rotate the Armor Rod. Rotate the armor rod around the conductor in a coiled manner, ensuring a grip distance of 1 to 1.5. This ensures a secure and stable installation.

Repeat the Process. Continue the installation process by repeating steps 2 and 3 to install the remaining preformed armor rods.

Secure the Rods. Depending on the direction of the spiral of the rods, wrap them all together at the end to ensure a secure and tidy installation. This completes the installation process.

In conclusion, preformed armor rods provide numerous advantages, including color coding for easy installation, damage repair capabilities, protection against vibration, compatibility with tapped conductors, and straightforward installation. By following the simple installation steps outlined above, you can ensure a successful and reliable installation of preformed armor rods.

Armor rods are suitable for maintenance using hot line tools and are fitted at suspension points of line conductors except for jumper suspension points.

Installation:

Install preformed armor rods in accordance with approved recommendations by Tronco Electric. Centre rods in each suspension clamp so that the variation from the center line of the clamp and the mid-point of the rod is not more than 50 mm. Exercise proper caution in seating the last few rods of the set so that the conductor surface is not damaged.