Forged Steel Ball Eye

- Information

- Product Description

- Video

- Download

Ball Clevis Introduction

Body: forged steel, hot dip galvanized

Hardware: galvanized steel

Cotter Pin: stainless steel

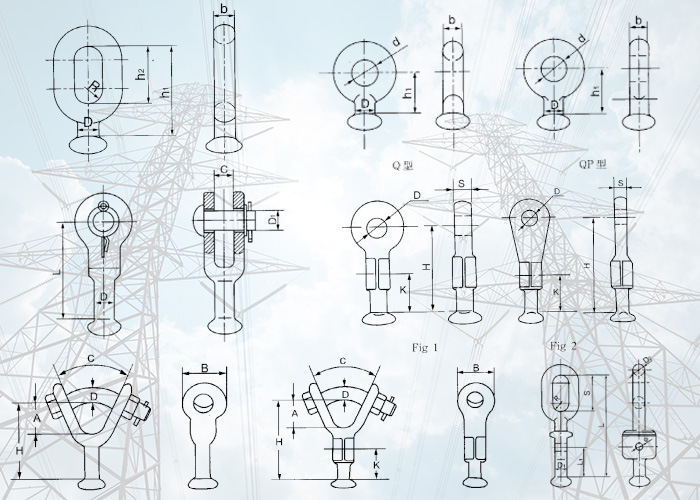

1. Technical specifications

Type | Suitable Insulator | Dimensions(mm) | Rated Failure Load (KN) | Weight (Kg) | ||||

h1 | h2 | R | D | b | ||||

QH-7 | U-70 | 114 | 57 | 11 | 17 | 16 | 70 | 0.6 |

QH-12 | U-120 | 120 | 63 | 11 | 17 | 16 | 120 | 0.7 |

QH-16 | U-160 | 130 | 70 | 13 | 26 | 20 | 160 | 1.0 |

QH-7A | U-70 | 90 | 52 | 11 | 17 | 16 | 70 | 0.5 |

2. Manufacture process

Round steel Cutting--Heating--Forging--Polishing-Hot dip galvanizing.

Galvanizing: The galvanized hardware fittings have a smooth and uniform thickness of zinc coating without any sharp edges. The fittings are galvanized after subjecting to the processes such as sawing, shearing, drilling, punching, filling, bending and machning.

3. Packing

Ball clevis are packed by plywood case on pallet, which is seaworthy and easy for transportation.

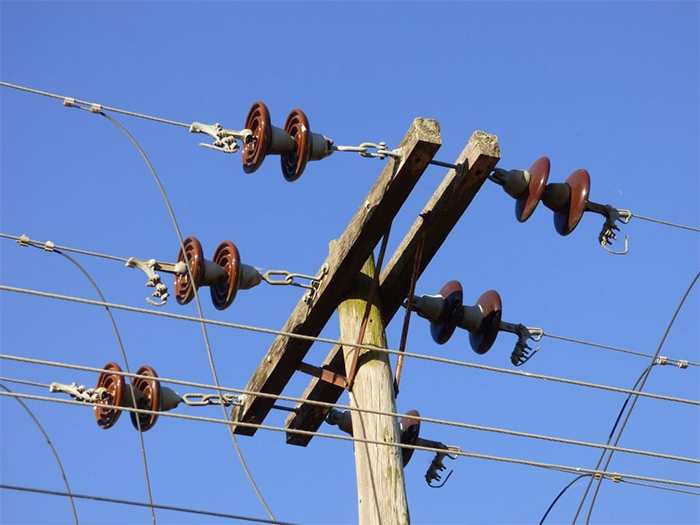

4. Ball clevis application

Link fittings, the ball clevis is fixed on the insulator with cap & pin metal fitting and anchor shackle for overhead lines. The ball clevis is suitable for tension insulator string, suspension insulator string, jumper insulator string, and earthing strings. Arcing horn should be fixed on the ball clevis for high voltage, or requested by client.

Manufacturing method: Forging

Surface: Hot dip galvanized

Strength: High-strength forged steel, from 40kN to 530kN

Standard: IEC 61284 & BS 3288

Galvanizing standard: BS 729 & ISO 1461