Transmission Line Strain Clamp

- Information

- Product Description

- Video

- Download

Tension Clamp Introduction

Tension clamps are used in transmission and distribution line construction, especially at the section and angle pole. The tension clamp NLD series are made of malleable casting iron conforming with IEC 61284, and all its corrodible parts are galvanized in conformity with BS 729 or equivalent. NLL series of strain clamps for transmission lines comes with insulation covers for extra protection. The dead-end strain clamp is made of aluminum and is preferable for overhead lines up to 11kV and above.

A Strain clamp with an insulation cover is ideal for all types of conductors.

1. Technical specifications

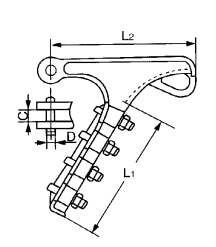

Type | Conductor Dia. (mm) | Dimensions(mm) | U Bolt No. | U.T.S (KN) | Weight(Kg) | |||

D | C | L1 | L2 | |||||

NLL1-1 | 5.1-11.4 | 16 | 19 | 108 | 126 | 2 | 40 | 1.7 |

NLL1-1.7 | 4.6-13.2 | 16 | 14 | 80 | 100 | 2 | 40 | 1.3 |

NLL1-2 | 8.9-18.5 | 16 | 24 | 187 | 176 | 2 | 40 | 3.2 |

NLL1-2C | 10.9-15.5 | 16 | 28 | 140 | 200 | 2 | 40 | 3.2 |

NLL1-2D | 11.7-21.8 | 16 | 30 | 140 | 200 | 2 | 40 | 3.1 |

NLL1-2M | 6.54-9.27 | 16 | 20 | 127 | 156 | 2 | 40 | 3.0 |

NLL1-3 | 5.1-14.5 | 16 | 17 | 187 | 203 | 3 | 70 | 5.3 |

NLL1-3A | 11.68-21.84 | 16 | 21 | 128 | 126 | 3 | 70 | 3.1 |

NLL1-3N | 12.6-23.4 | 16 | 22 | 150 | 130 | 3 | 70 | 3.2 |

NLL1-3U | 9.5-21 | 16 | 25 | 120 | 156 | 3 | 70 | 3.8 |

NLL1-4 | 9.1-21.8 | 16 | 26 | 275 | 292 | 4 | 90 | 7.4 |

NLL1-4A | 18.1-24.8 | 18 | 30 | 298 | 284 | 4 | 102 | 7.4 |

NLL1-5 | 24.0-30.0 | 24 | 36 | 446 | 342 | 5 | 120 | 9.2 |

NLL1-5A | 25.2-36.2 | 18 | 32 | 235 | 280 | 5 | 80 | 8.3 |

NLL1-6A | 25.0-38.0 | 18 | 36 | 245 | 300 | 6 | 80 | 9.8 |

The tension (strain) clamp is bolted type and suitable for use on Aluminium conductor steel reinforced (ACSR), the clamp has cotter bolts, U-bolts, and a pin, the number of bolts is 3, 4, or 5.

The tension clamp has a slip strength of not less than 85% of the rated ultimate strength of the conductor it is intended for use with.

1) The body and the keeper are manufactured from aluminum alloy containing a maximum of 0.4% Cu in accordance with EN 515 and EN 755-2: 2008 such as designation 6061-T6.

The alloy is resistant to inter-crystalline, layer, and stress corrosion. Further properties of the alloy:

a) hardness min 95HBW

b) Resistivity max. 40nΩm at 20℃

c) Proof stress min. 276MPa

d) Tensile strength min. 310MPa

e) A50% elongation at break min. 12%

2) Threaded inserts-to provide sufficient resistance to corrosion threaded inserts are made from stainless steel with a minimum quality equivalent to A2 of EN ISO 2506.

3) Straps are made from hot-dip galvanized steel. The thickness of the zinc coating is at least 80μm and meets the requirements according to ISO 1461

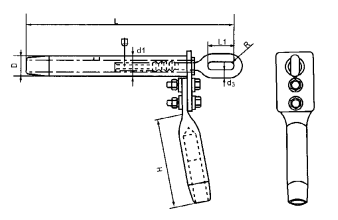

Type | Suitable Conductor | Dimensions(mm) | Slip strength (KN) | Weight (Kg) | ||||||

D | d1 | d3 | L | L1 | R | H | ||||

NY-170 | LINNET | 32 | 16 | 16 | 430 | 60 | 10 | 240 | 60.20 | 2.9 |

NY-183 | LYNX | 32 | 18 | 18 | 440 | 65 | 11 | 240 | 75.71 | 2.9 |

NY-240 | HAWK | 36 | 18 | 18 | 480 | 65 | 11 | 250 | 82.48 | 3.2 |

NY-241 | HEN | 36 | 20 | 20 | 490 | 78 | 12 | 250 | 99.44 | 3.3 |

NY-248 | LARK | 36 | 20 | 18 | 490 | 68 | 11 | 250 | 85.93 | 3.3 |

NY-282 | DOVE | 40 | 18 | 20 | 500 | 78 | 12 | 280 | 100.64 | 3.5 |

NY-264 | BEAR | 40 | 22 | 20 | 520 | 78 | 12 | 280 | 105.83 | 3.6 |

NY-306 | SQUAB | 40 | 18 | 20 | 500 | 78 | 12 | 280 | 102.98 | 3.5 |

NY-322 | GROSBEAK | 40 | 20 | 22 | 540 | 83 | 13 | 280 | 107.17 | 3.9 |

NY-376 | TEAL | 45 | 22 | 22 | 550 | 83 | 13 | 280 | 126.75 | 4.1 |

NY-402 | CONDOR | 45 | 20 | 22 | 590 | 83 | 13 | 300 | 119.29 | 4.2 |

NY-428 | ZEBRA | 48 | 20 | 22 | 600 | 83 | 13 | 300 | 125.31 | 4.3 |

NY-445 | REDWING | 48 | 24 | 24 | 600 | 95 | 15 | 300 | 146.32 | 4.5 |

NY-468 | DRAKE | 48 | 22 | 22 | 620 | 83 | 13 | 320 | 132.52 | 5.4 |

NY-494 | MALLARD | 48 | 26 | 24 | 620 | 95 | 15 | 320 | 163.00 | 5.4 |

NY-483 | RAIL | 48 | 18 | 20 | 620 | 78 | 13 | 340 | 109.60 | 6.4 |

NY-564 | BLUEJAY | 52 | 18 | 22 | 620 | 78 | 13 | 340 | 126.75 | 6.8 |

NY-546 | CARDINAL | 52 | 20 | 24 | 620 | 95 | 15 | 320 | 143.52 | 6.8 |

NY-604 | GRACKLE | 60 | 26 | 24 | 670 | 95 | 15 | 350 | 178.93 | 7.2 |

The body and jumper clamp is made of aluminum, other parts are made of hot-dip galvanized steel.

2. Fabrication plant

3. Packing and storage

The tension clamps are packed in the plywood case and are easy to store.

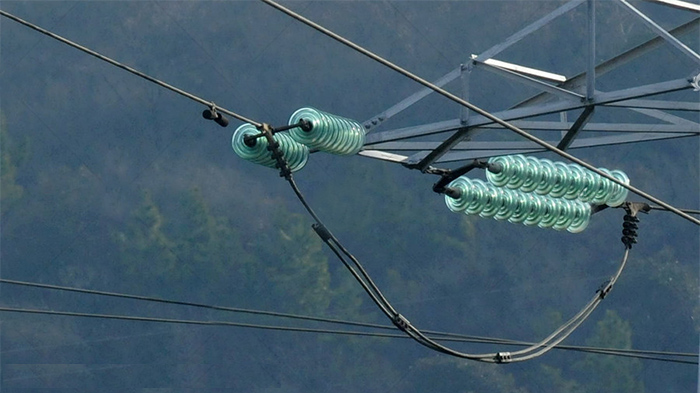

4. Strain clamps application

The tension clamps are used for the tension strings in the transmission and distribution lines.

1. Dead-end clamp for ACSR conductor (compression type)

2. Aluminum alloy strain clamp (bolted type)

3. Malleable iron strain clamp (bolted type)

4. Straight line type

Tronco Electric provides the design according to the client's specifications and requirements.