- Home

- >

- Products

- >

- Stay Insulator

- >

Stay Insulator

- Information

- Product Description

Stay Insulator Induction

The insulating material of strain insulators is porcelain, which is sound, thoroughly vitrified, and free from defects and blemishes which might adversely affect the life of the insulator. The exposed parts of the porcelain are smoothly glazed and brown in color.

The strain insulator is free from stresses due to expansion and contraction in any part which may lead to deterioration. The holes in the insulator are smoothly radiused with as large a radius as practicable to present an even bearing surface to the stay-strand loop.

1. Technical datasheet

The porcelain insulators are strain type suitable for stay wire, there are MV and LV stay insulators in the distribution line. Tests are based on ANSI or IEC standards.

ANSI standard

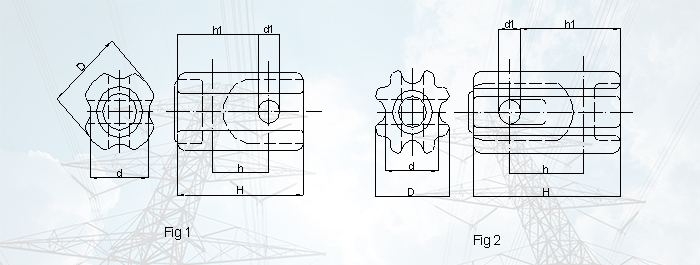

Fig. No. | 1 | 2 | ||||

ANSI Class | 54-1 | 54-2 | 54-3 | 54-4 | ||

Nominal System Voltage/kV | 2.2 | 4.4 | 6.6 | 6.6 | ||

Main Dimensions/in | H | 3-1/2 | 4-1/4 | 5-1/2 | 6-3/4 | |

h | 1-3/4 | 2-1/4 | 3-1/8 | 2-5/8 | ||

h1 | 2-1/2Max | 3 Max | 4-1/16 | 4-1/2 | ||

D | 5/8 | 2-7/8 | 3-3/8 | 3-1/2 | ||

d | 1-3/4 | 2-1/8 | 2-3/8 | 2-3/8 | ||

d1 | 2-1/2 | 7/8 | 1 | 1 | ||

Tension Strength/Ib(KN) | 10,000(44) | 12,000(53) | 20,000(89) | 20,000(89) | ||

Average Flashover Voltage/kV | Low-frequency(Dry) | 25 | 30 | 35 | 40 | |

Low-frequency(Wet) | 12 | 15 | 18 | 23 | ||

Leakage Distance/in(mm) | 1-5/8(41) | 1-7/8(48) | 2-1/4(57) | 3(76) | ||

Net Weight/Ib(kg) | 0.76(0.35) | 1.5(0.68) | 2.9(1.3) | 4.1(1.9) | ||

IEC standard

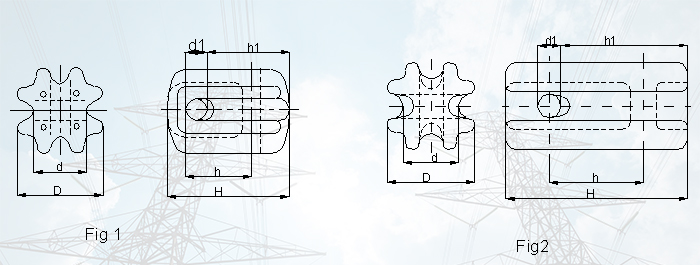

Fig. No. | 1 | 2 | 2 | 2 | |

Class | GY1 | GY2 | GY3 | GY4 | |

Dimensions, mm | H | 90 | 146 | 216 | 280 |

h | 48 | 73 | 89 | 89 | |

h1 | 60 | 99 | 133 | 165 | |

D | 68 | 73 | 115 | 115 | |

d | 40 | 44 | 67 | 67 | |

d1 | 16 | 22 | 38 | 38 | |

Power Frequency Withstand Voltage (Wet), kV | 10 | 15 | 20 | 30 | |

Tension Failing Load, KN | 27 | 71 | 222 | 222 | |

Net Weight, Each, Approx., kg | 0.6 | 1.1 | 4.3 | 5.7 | |

2. Manufacture process

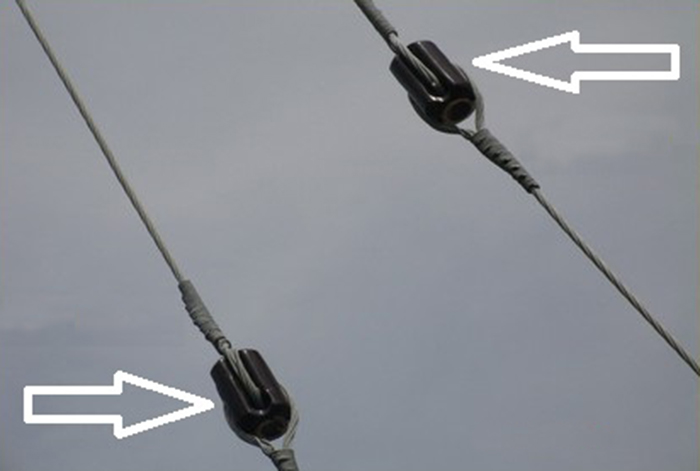

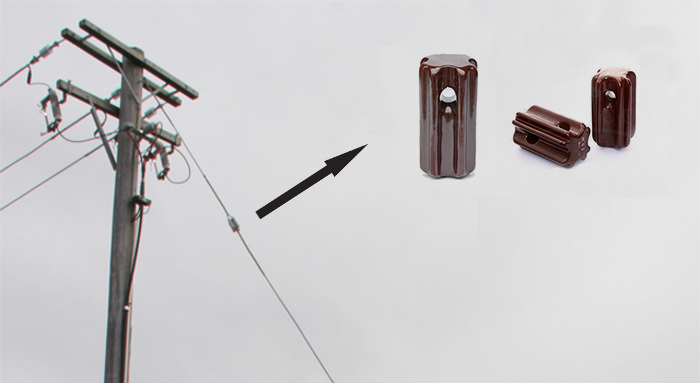

3. Guy insulator application

The stay insulators are manufactured by wet process and are designed for insulation of stays to reduce the risk of dangerous potential gradients at ground level and in the case of stays on earthed structures, to prevent electrolytic corrosion of stay rods.