Composite Line Post Insulators

- Information

- Product Description

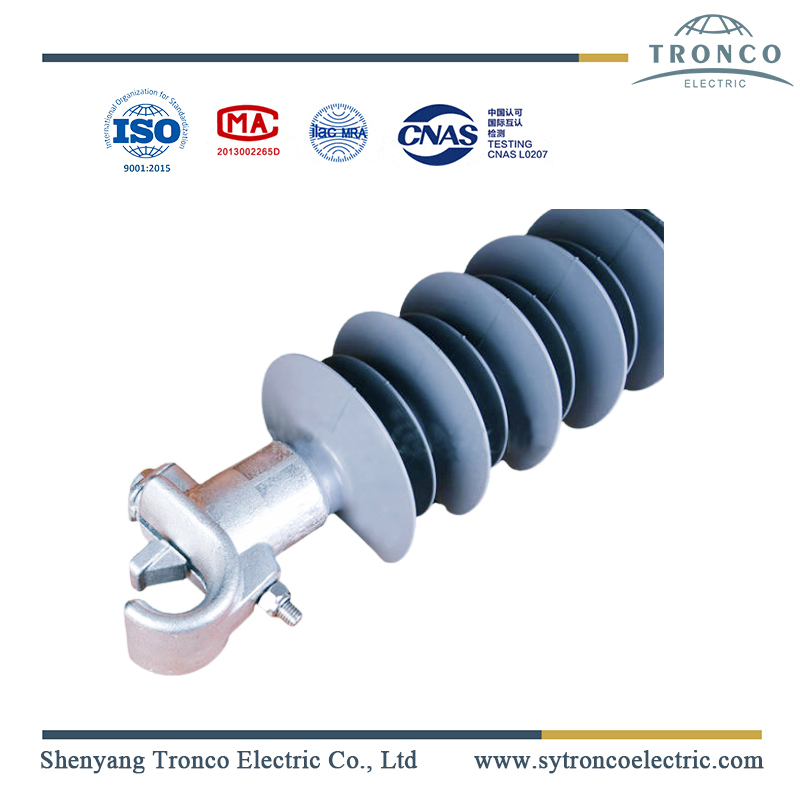

Composite Line Post Insulator

The Composite Line Post Insulator is specially designed to meet the electrical insulation requirements for horizontal and vertical line post applications. It is a durable and reliable solution that ensures safe transmission of electrical power. With its advanced features and high-quality construction, this insulator offers superior performance in various environmental conditions.

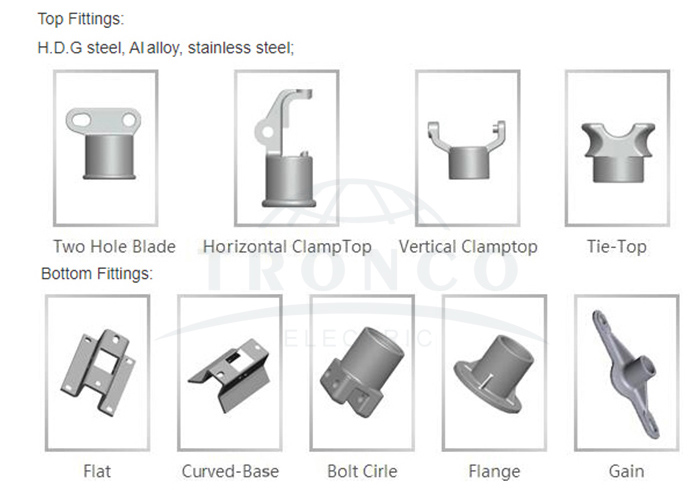

The line end fitting of the Line Post Insulator is available in four different configurations: Horizontal or Vertical Clamp-Top, Tie-Top, or K-clamp. End fittings on line Post Insulators are made of corrosion-resistant aluminum alloy or galvanized iron castings.

Standards:

IEC 61109 Composite tensioin and suspension insulators

IEC 61952 Composite line post insulators

IEC 61466-1 Standard strength classes and end fittings

ISO 1461 Hot-dipped galvanised coatings on fabricated iron and steel articles

Key Features

Electrical Grade Epoxy and Corrosion Resistant E-Glass Fibre (ECR Rod): The insulator is made of high-quality materials that provide excellent electrical insulation and protection against corrosion, ensuring long-lasting performance.

HTV Silicone Rubber Sheds and Housing: The insulator features high-temperature vulcanized (HTV) silicone rubber sheds and housing, which maintain hydrophobicity, resistance to tracking, erosion, and aging even in polluted areas.

Galvanized Forged Steel End Fittings: The insulator is equipped with galvanized forged steel end fittings that offer exceptional strength and durability, guaranteeing reliable performance in demanding applications.

Compression of End Fittings: The end fittings of the insulator undergo compression using a multi-part die, ensuring uniform distribution of load. The process is acoustically monitored to ensure the core is in sound condition after crimping.

Hydrophobic and Self-Cleaning: Thanks to its hydrophobic properties, the insulator resists moisture absorption, reducing the chances of flashovers. Additionally, the self-cleaning feature ensures that pollutants and contaminants are easily shed off, maintaining optimal performance.

Lightweight and Impact Resistant: The insulator is lightweight, making it easier to handle during installation. Despite its lightweight design, it is highly impact resistant, providing reliable protection against impacts and other mechanical stresses.

Easy Installation and Low Maintenance: Installing the insulator is a hassle-free process, and it requires minimal maintenance over its service life. This reduces downtime and ensures continuous operation without significant interruptions or additional costs.

Less Prone to Vandalism: Due to its material composition and sturdy construction, this insulator is less susceptible to vandalism, ensuring the integrity of the power transmission network.

Specifications

Type: Composite Line Post Insulator

Material: Electrical Grade Epoxy and Corrosion Resistant E-Glass Fibre (ECR Rod)

Sheds and Housing: HTV Silicone Rubber

End Fittings: Galvanized Forged Steel

Weight: Depends on the specific model and length

Color: Gray or Brown

How does it work?

The Composite Line Post Insulator functions by providing electrical insulation between the conductors and the supporting structure. It prevents the flow of electrical current through the structure, ensuring safe and efficient power transmission. The high-quality materials used in its construction, such as the electrical grade epoxy and E-glass fiber, along with the HTV silicone rubber sheds and housing, ensure reliable insulation and protection against environmental factors.

FAQs (Frequently Asked Questions)

Q: Is the composite line post insulator suitable for both horizontal and vertical line post applications?

A: Yes, the composite line post insulator is specifically designed to meet the insulation requirements for both horizontal and vertical line post applications.

Q: Can this insulator withstand harsh environmental conditions?

A: Absolutely. The insulator's HTV silicone rubber sheds and housing provide excellent resistance to tracking, erosion, and aging. This makes it highly suitable for use in polluted areas or areas with harsh environmental conditions.

Q: Does the insulator require regular maintenance?

A: The composite line post insulator is designed for low maintenance. Its self-cleaning properties and durable construction minimize the need for regular maintenance, reducing downtime and costs.

Q: Is this insulator easy to install?

A: Yes, the insulator is designed for easy installation. Its lightweight design, combined with the ease of handling, simplifies the installation process.

Q: Is the insulator resistant to impact?

A: Yes, the composite line post insulator is highly impact resistant, providing reliable protection against impacts and mechanical stresses.

Invest in the Composite Line Post Insulator today and ensure reliable and safe power transmission. Its advanced features, sturdy construction, and low maintenance requirements make it the ideal choice for various line post applications.

Material: Electrical Grade Epoxy and Corrosion Resistant E-Glass Fibre (ECR Rod)

Sheds and Housing: HTV Silicone Rubber

End Fittings: Galvanized Forged Steel

Weight: Depends on the specific model and length

Color: Gray or Brown