- Home

- >

- Products

- >

- Line Post Insulator

- >

Line Post Insulator

- Information

- Product Description

Production Description

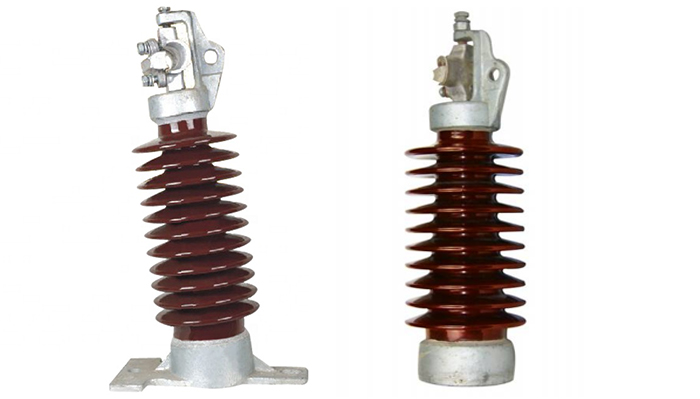

A porcelain line post insulator is a rigid insulator, that consists of an insulating material permanently assembled with a metal base to be mounted rigidly on a supporting structure with a metal base attached by means of a stud or one or several bolts. The design of the line post insulator facilitates inspections, cleaning, repairs, and hotline maintenance.

1. Porcelain line post insulator structure

The line post insulator is made of good commercial-grade wet-process porcelain. The top/side conductor groove (tie top or clamp type) is suitable for attaching aluminum conductors with cross-sections specified in the tender specifications.

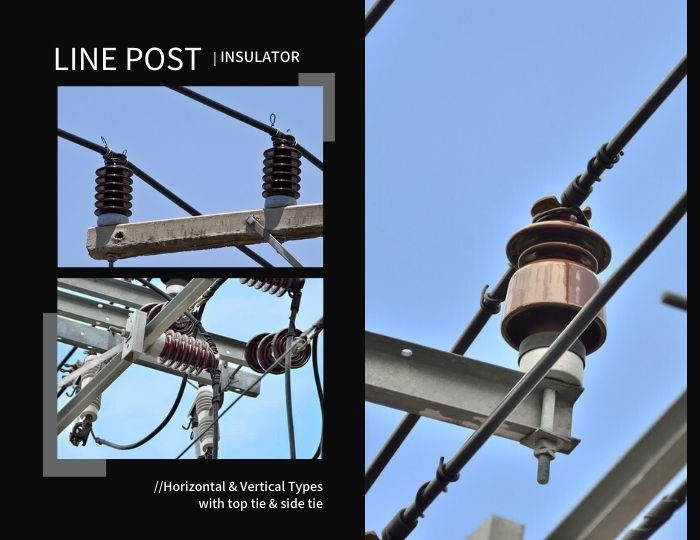

1) Horizontal line post insulator

2) Vertical line post insulator

The line post insulator is supplied complete with the necessary hardware for line end fitting and base end fitting to metallic, wood, and concrete poles, the line post insulator is suitable to support the line conductor in horizontal and vertical positions.

Galvanizing

All iron and steel parts are galvanized after subjecting to the processes such as sawing, shearing, drilling, punching, filing, bending, and machining. Galvanizing shall be applied by hot dip process to comply with the ISO 1461 specified. The thickness of zinc coating is not less than the minimum thickness specified in ISO 1461.

Finishing

The insulator surface is smooth, uniform, and the glazed area is free of surface irregularities such as sharp edges, cavities, dents, and unglazed spots, etc. The galvanized hardware fittings of line post insulator have a smooth and uniform thickness of zinc coating without any sharp edge

2. Technical specifications

Rated line voltage/kV | 20 | 25 | 35 | 45 | 55 | 66 | 88 | ||

ANSI Class | _ | 57-1 | 57-2 | 57-3 | 57-4 | 57-5 | 57-6 | ||

Designation of Neck | F | F | F | F | N | N | N | ||

Height” A”/in(mm) | 7-1/2 (191) | 8-3/4 (222) | 12 (305) | 14-1/2(369) | 17 (432) | 20 (508) | 23 (584) | ||

Diameter ”B”/in(mm) | 5-1/2 (140) | 5-3/4 (146) | 5-3/4 (146) | 6 (512) | 7 (178) | 7 (178) | 7-5/16(185) | ||

Diameter ”C” /in(mm) | 3-3/4 (95) | 4 (102) | 4 (102) | 4-1/2 (114) | 5 (127) | 5 (127) | 5-1/2 (140) | ||

Thread ”D” /in(mm) | 3/4-10UNC | 3/4-10UNC | 3/4-10UNC | 3/4-10UNC | 3/4-10UNC | 3/4-10UNC | 7/8-9UNC | ||

Min. leakage distance/in(mm) | 11 (280) | 14 (356) | 22 (559) | 29 (737) | 40 (1015) | 45 (1145) | 53 (1345) | ||

Dry arcing distance/in(mm) | 5-3/4 (146) | 6-1/2 (165) | 9-1/2 (241) | 12-1/4(311) | 14-1/2(368) | 17-1/4(438) | 19-1/4(489) | ||

Cantilever strength/lb(kN) | 2000 (9) | 2800 (12.5) | 2800 (12.5) | 2800 (12.5) | 2800 (12.5) | 2800 (12.5) | 2800 (12.5) | ||

Average flashover voltage | Low Frequency | Dry/kV | 80 | 80 | 110 | 125 | 150 | 175 | 200 |

Wet/kV | 55 | 60 | 85 | 100 | 125 | 150 | 170 | ||

Critical Impulse | Pos. /kV | 105 | 130 | 180 | 210 | 255 | 290 | 330 | |

Neg. /kV | 130 | 155 | 205 | 260 | 340 | 380 | 425 | ||

Withstand voltage | Low frequency | Dry/kV | 60 | 60 | 90 | 100 | 120 | 140 | 160 |

Wet/kV | 40 | 45 | 65 | 80 | 100 | 120 | 135 | ||

Impulse/kV | 85 | 110 | 150 | 170 | 200 | 235 | 250 | ||

Radio influence voltage data | Test voltage/kV | 15 | 15 | 22 | 30 | 44 | 44 | 44 | |

Max. RIV at 1,000kHz/μV | 50 | 100 | 100 | 200 | 200 | 200 | 200 | ||

Net weight/lb(kg) | 8.5 (3.9) | 11 (5) | 17 (7.7) | 22 (10) | 36 (16) | 46 (21) | 51 (23) | ||

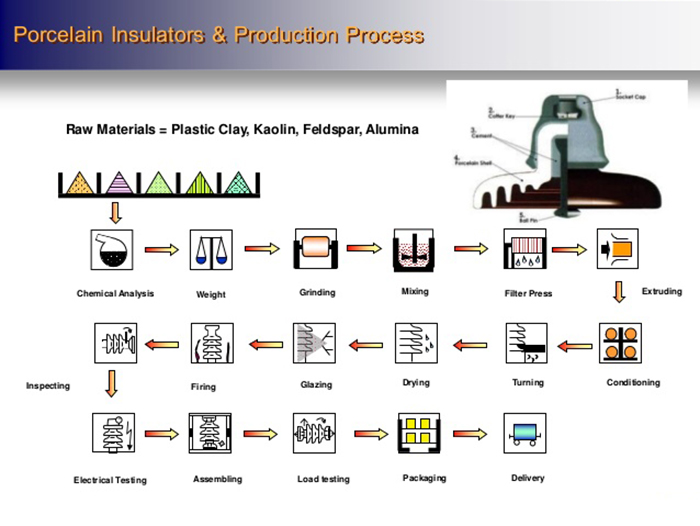

3. Manufacture process

4. Inspection

The porcelain line post insulator is to be tested according to IEC or ANSI standards.

In the factory, routine and sample tests are to be performed.

5. Application

The Porcelain line post insulator is used for HV and MV overhead lines to support the conductors.

• Enables compact OHTL design

• Braced applications offer extra high strength

• Superior pollution performance (hydrophobicity transfer mechanism)

• Earthquake resistant

• Vandalism proof

• Fail-safe arrangements (bendable bases)

• Able to withstand extreme dynamic and impact loads

• Lightweight: easy transport, handling, and installation

• Flexible in design (modular system)

• Technology has proven since more than 20 years