OPGW Suspension Assembly

- Information

- Product Description

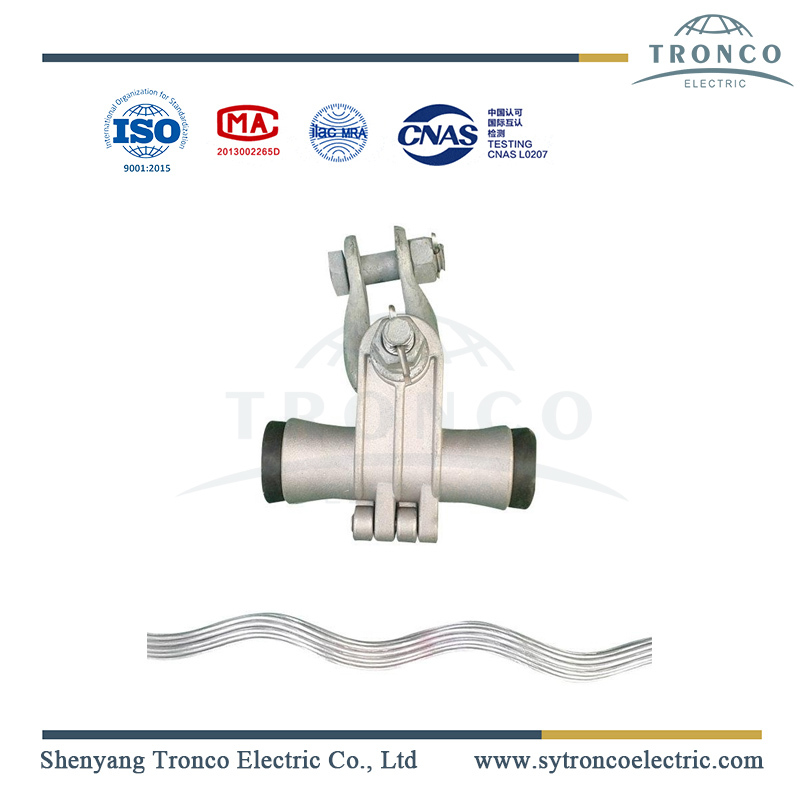

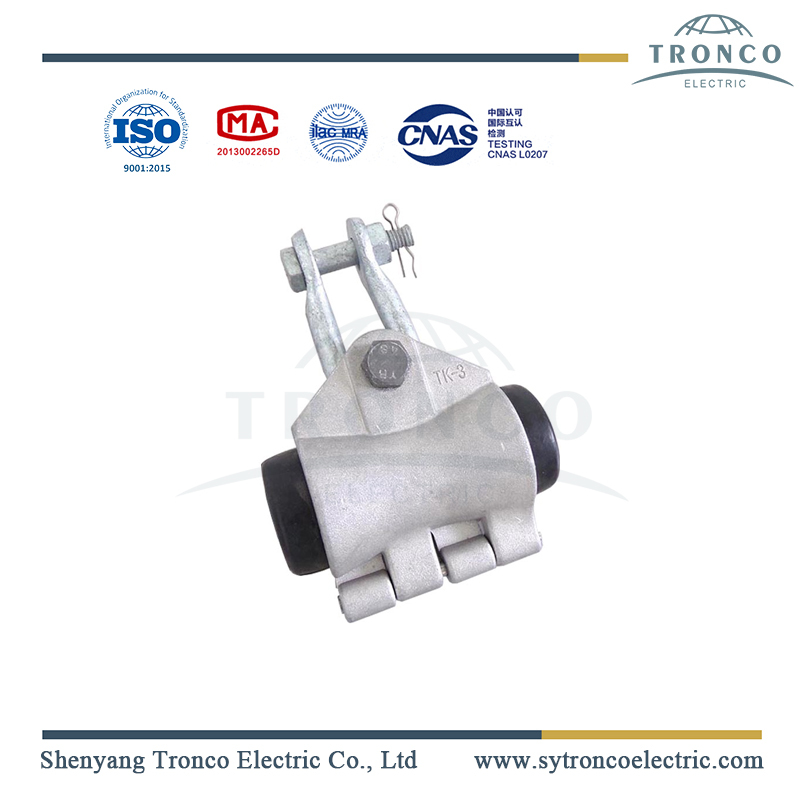

Suspension Clamp for OPGW Introduction

The suspension clamp for OPGW is equipped with twisted wire (Armor Rods) on neoprene protective sleeve cable and twisted wire between the sleeve and clamp.

Neoprene or other non-metallic material has good resistance to aging and can withstand temperatures between + 10 ° C and + 55 ° C without modification of its essential properties. This material also has adequate resistance to ultraviolet rays, ozone, or pollution factors.

In the case of castings, additional reinforcement spiral rods made of aluminum alloy are needed, and the diameter is not less than 4mm.

The material composing the clamps meets the EN 1559 standard for aluminum alloy castings and the EN 1562 standard for malleable cast iron.

The axis of rotation of the gripper is in the longitudinal axis of the ground wire/OPGW to avoid any inadmissible distortion of the ground wire / OPGW caused by unbalanced longitudinal loads.

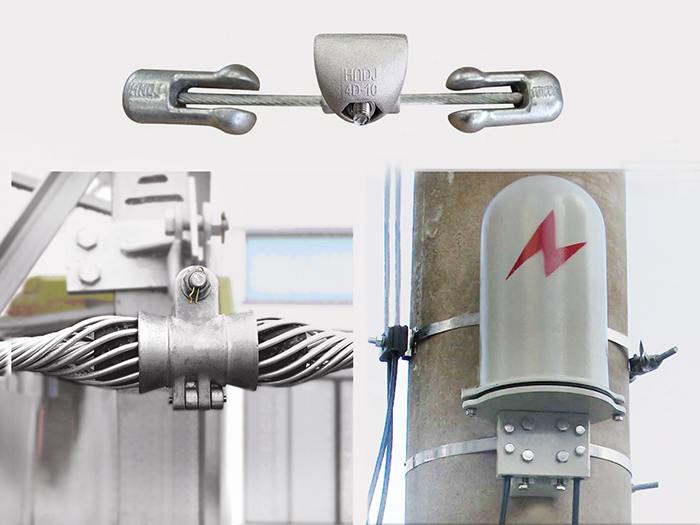

All the ferrous parts of the elements composing the assemblies and the accessories for the conductors, and ground cables are hot-dip galvanized according to the ISO 1461 standard. The cotter pins of all the clamps and reinforcements are in stainless steel.

All metal parts other than stainless steel are galvanized in accordance with the applicable standard. The minimum thickness of the zinc coating on the angles, plates, and gussets is 85μm, and on bolts 55μm.