ALTERNATIVE TYPES OF STATION POST INSULATORS

2023-03-10 17:30Porcelain Station Posts

Porcelain station post insulators cover a voltage range up to 765 (800) kV, with maximum cantilever strength classes in the range 20 to 30 kN. Single units can be manufactured to a length of 3000 mm. For voltage levels exceeding 245 kV, assemblies (or multi-unit stacks) are used consisting of 2 or more individual units connected by metal flanges. Standard IEC 60273 is applicable for selection of IEC types according to characteristic values and the related test standard is IEC 60168. Post insulators according to ANSI standard C29.9 are defined as a 'catalogue' (TR types) according to characteristic values and covering types up to 765 kV. ANSI C29.9 also defines applicable tests. Porcelain station posts in accordance with IEC 60273 and ANSI C29.9 are today well specified and can be ordered according to C- or TR-Codes respectively. However both standards are relatively old and need revision in order to accommodate the latest technologies as well as updated definitions of pollution classes as per IEC 60815-2. Modern production technologies offer high-strength designs optimized in shape, weight and shed profile. For applications under severe pollution, RTV silicone coatings can be used to improve electrical performance.

Composite Station Posts (CSP): Solid Core Type

CSPs, first introduced during the early 1980s, consist of a solid core fiber reinforced polymeric (FRP) core and an elastomeric housing. Typical FRP core diameters range from 45 to 100 mm with maximum diameters rarely exceeding 130 mm. Application in substations derived from past application of composite line post (CLP) insulators, mainly in the United States. CSPs with solid cores are typically applied up to 245 (420) kV. For higher voltage classes, relatively high mechanical deflection limits their broader application. The test standard for this product is IEC 62231 while mechanical and electrical characteristics are defined in IEC 62231-1, which also includes ANSI types utilized in North America. C29.19 is the relevant standard for such ANSI types.

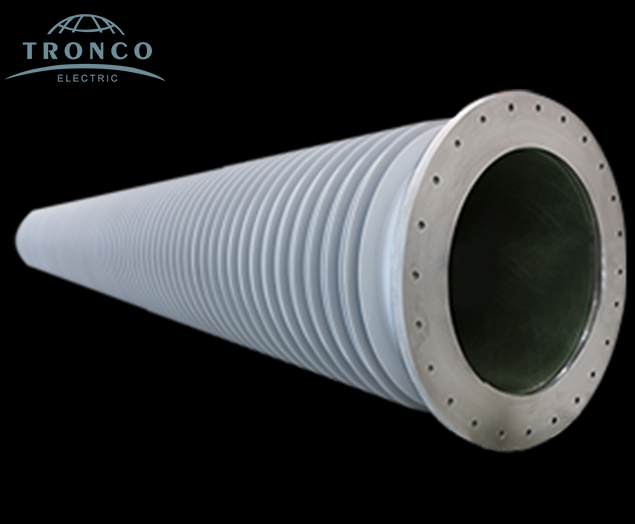

Composite Station Posts: Hollow Core Type (CHSP)

At voltage classes higher than 245 kV, height and bending moment of stations posts both increase. As a result, much effort is needed to satisfy application requirements using solid core CSP designs (i.e. with core diameters >170 mm). This makes this technology less cost competitive versus porcelain types. At the same time, composite hollow core station posts (CHSP) and hybrid station post (HSP) insulators have begun to enter this application portfolio. For example, CHSPs have already been realized for 800 kV HVDC and 1100 kV UHV applications, with connection length of more than 10 m and tube diameters of 500 to 1000 mm. Bending moments of more than 1000 kNm are feasible with this technology. The hollow volume inside these posts has to be filled with some electrically inert medium e.g. insulating gas foam. The applicable test standard is IEC 62772.

Hybrid Station Posts (HSP)

Hybrid station posts, according to IEC TR 62896, are combinations of porcelain (ceramic) and composite (polymeric) technologies. The core of an HSP is typically solid core porcelain made from high-strength mass (C-130) while the housing is made of an elastomeric material, whether liquid silicone rubber (LSR) or high temperature vulcanized (HTV) silicone. These are applied by means of injection molding or some extrusion process. The advantages of HSPs are low deflection of the rigid porcelain core with high E-modulus under cantilever load. Moreover, the hydrophobic silicone housing improves electrical properties under polluted conditions. Typical applications are large HVDC post installations as well as posts for disconnector switches (i.e. where low deflection is required)

PS:www.inmr.com-application-of-station-posts