Quality issues of Composite Insulator End Sealing

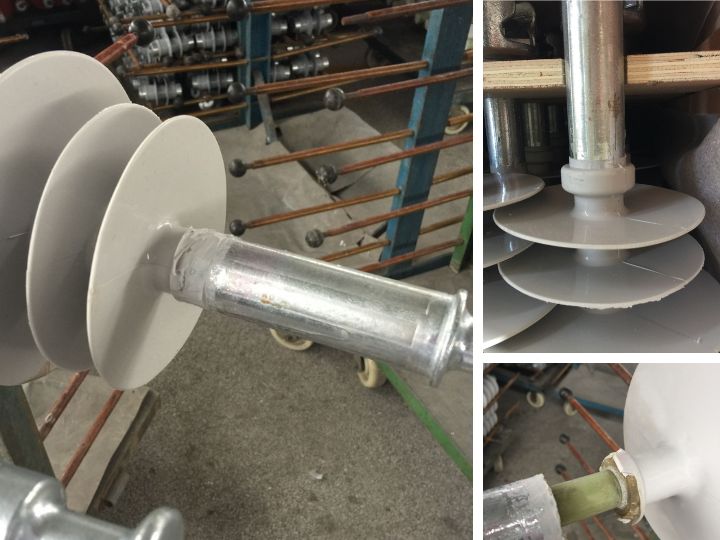

2023-05-05 23:07Currently, most of the end connection structures of organic composite insulators produced in China use wedge connections, and some manufacturers adopt the crimp connection structure imitating foreign countries. However, whether it is a wedge joint or a crimp joint, there is a problem with the sealing process at the joint between the end fitting and the mandrel sheath. Most domestic manufacturers use the sealant, and manually applying the sealant often has certain quality risks.

1) First of all, it is inevitable for the composite insulator to slip between the mandrel and the fitting during long-term load operation (wedge joint). When the adhesive force between the sealant and the hardware is poor, a small slip is enough to make the seal open, and when the sealant is not elastic enough, excessive slip can cause the sealant to break.

2) Secondly, most of the sealants produced in China are room-temperature silicone rubber. Its anti-aging performance is obviously not as good as that of high-temperature vulcanized silicone rubber. In the case of corona at the end fittings, it may cause premature aging. For products of 110kV and below, no voltage equalizing ring is used, or when the voltage equalizing ring is improperly installed for products of 220kV and above, there will be a greater danger.

3) Since the process of applying sealant is a manual application, there will be some uncertain factors, the operation process is not easy to control, and it is not easy to manage and control product quality.